Choosing a centrifuge is rarely about “the fastest machine.” In real labs, the right choice is the one that matches your samples, your workflow, and your separation goal—whether that’s clean layer separation for blood tubes or fast clarification in microtubes. That’s why many buyers compare a high speed centrifuge with a low-speed (or medium-speed) model and still feel uncertain after looking at RPM numbers alone.

This guide makes the decision practical. You’ll get a clear comparison chart, a task-based selection table, and a troubleshooting checklist—so you can choose confidently and avoid common mistakes that affect results.

1. What “High-Speed” and “Low-Speed” Really Mean

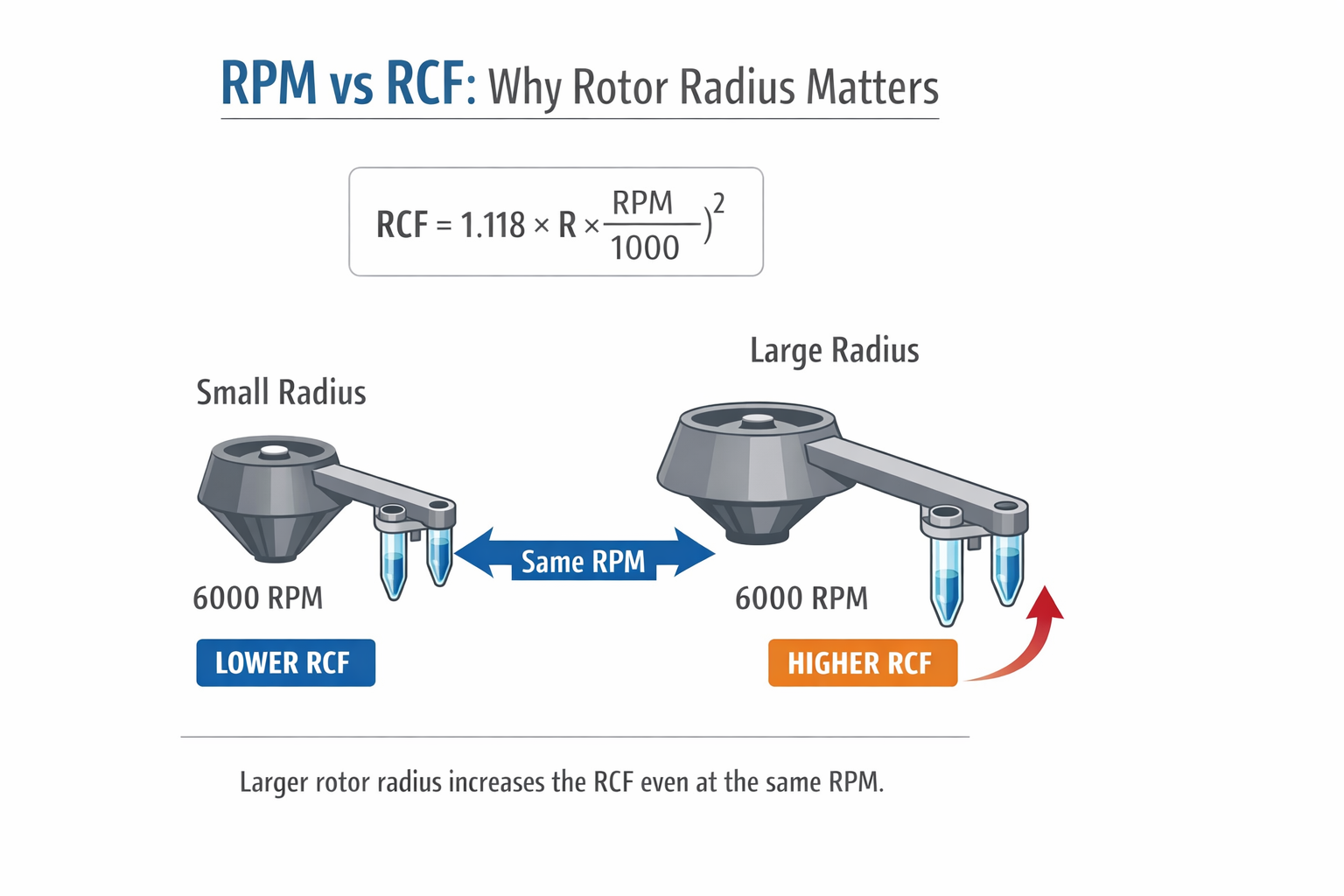

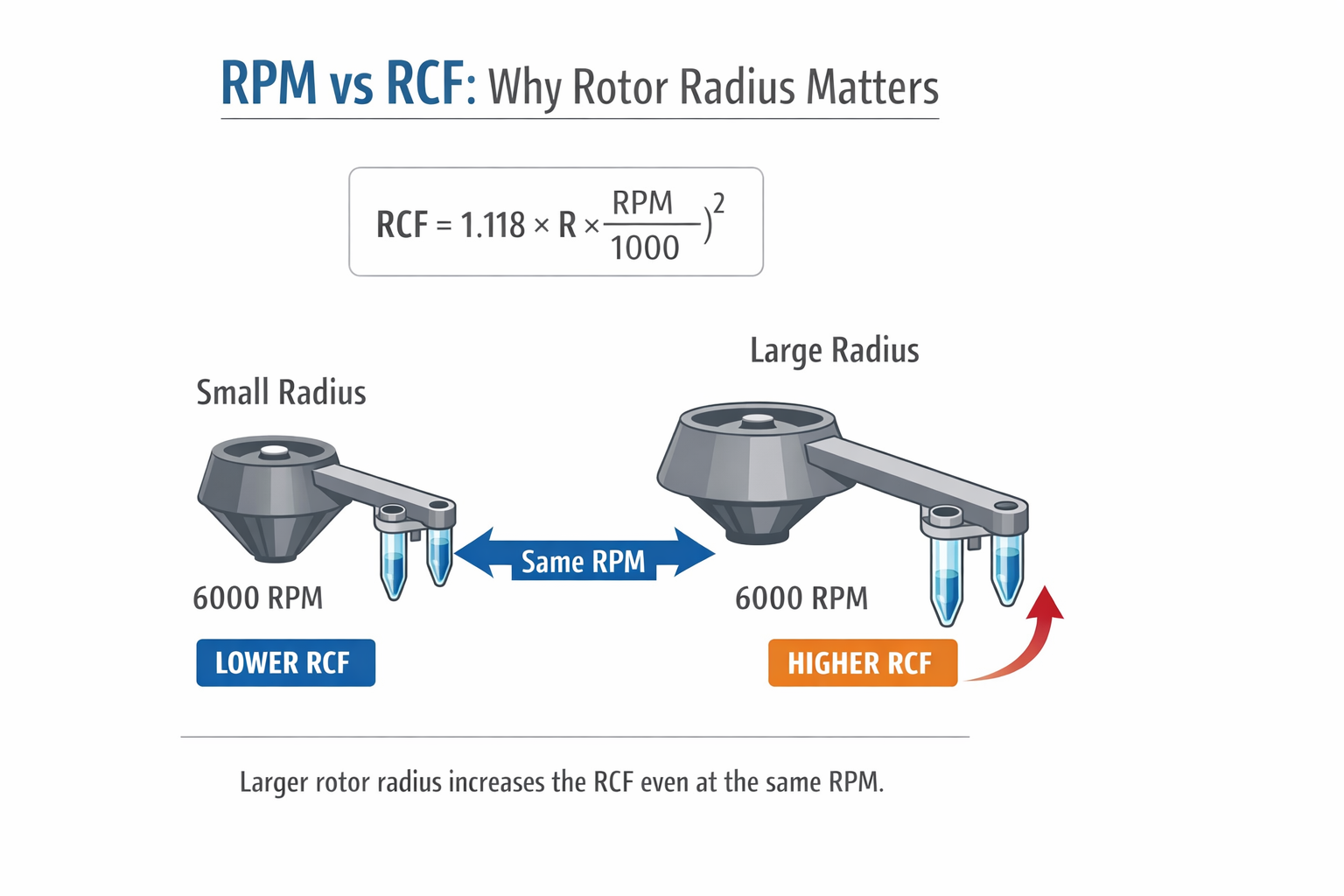

People often define centrifuges by maximum RPM, but in practice, RCF (relative centrifugal force, or “g-force”) is what drives separation performance. RCF depends not only on RPM but also on the rotor radius. Two machines can run at the same RPM and produce different g-force values if the rotor geometry differs.

Diagram explaining RPM vs RCF and how rotor radius affects centrifuge g-force.

In other words: when comparing a high speed centrifuge and a low-speed centrifuge, treat speed as one part of a bigger system that includes rotor type, tube capacity, temperature control, run time, and safety features.

2. High-Speed vs Low-Speed Centrifuge Comparison Chart

If you only read one part of this article, make it this chart. It summarizes how the two categories differ in real purchasing decisions—performance, use cases, and operating trade-offs.

TABLE 1 — High-Speed vs Low-Speed Centrifuge

Category | High-Speed Centrifuge | Low-Speed / Medium-Speed Centrifuge |

Typical goal | Faster separation, higher g-force tasks | Routine separation, gentle handling, larger tubes |

Best for samples | Microtubes, fast clarification, pellet formation | Blood tubes, cell separation, general clinical/lab routines |

Speed & force focus | Higher RPM/RCF range (application-driven) | Lower RPM/RCF range (routine protocols) |

Rotor options | Often fixed-angle + micro rotors; some support plates | Often swing-out for layer separation; large-capacity rotors common |

Capacity style | Smaller tubes but higher throughput per hour | Larger tubes and batch-friendly runs |

Temperature impact | More likely to warm samples at long/high runs | Usually lower heat load; refrigerated models still matter for some tasks |

Precision needs | Balancing and adapters become more critical | Balancing still required, often more forgiving |

Noise & vibration | Can be more sensitive at higher speeds | Typically lower vibration profile (depends on build and rotor) |

Safety priorities | Lid lock, overspeed, imbalance detection are crucial | Same safety fundamentals; often simpler operation |

Cost of ownership | Higher rotor/accessory sensitivity; higher spec parts | Often lower entry cost; strong value for routine tasks |

Typical buyers | Research labs, biotech workflows, mixed micro-sample work | Clinics, routine labs, education, general-purpose workflows |

How to use this table:

If your work is dominated by micro-volume, higher g-force, faster clarification, a high speed centrifuge is usually the better match.

If you mainly run blood tubes, routine separations, or larger batch volumes, low/medium-speed models often deliver better practicality per dollar.

3. Application-Based Selection

Instead of starting with “How fast can it go?”, start with your sample type + your separation outcome. That mindset prevents overbuying and helps you avoid inconsistent results.

A) If your work is blood separation or routine clinical tasks

For blood tubes, consistent layer separation and stable rotor compatibility often matter more than extreme speed. Many workflows prioritize swing-out rotors, tube adapters, and repeatability across daily runs.

B) If your work is micro-volume, pellets, and fast clarification

A high speed centrifuge becomes valuable when you need stronger separation forces or when time matters—especially for microtubes and small-volume protocols. In these scenarios, rotor selection and balancing discipline strongly affect reliability.

TABLE 2 — Task-to-Model Selection Guide

Your task | Recommended type | Rotor style to consider | Why it fits | Common mistake |

Blood tube separation / serum-plasma | Low/medium-speed (often swing-out) | Swing-out rotor | Helps layer formation and consistent separation | Choosing based on RPM only, ignoring rotor/tube match |

Cell collection (routine) | Low/medium-speed or refrigerated if needed | Swing-out or fixed-angle | Gentle handling and scalable capacity | Over-spinning leading to cell damage |

Microtube clarification | High speed centrifuge | Fixed-angle micro rotor | Faster clarification and stronger g-force | Poor balancing with adapters |

Pellet formation (small volume) | High speed centrifuge | Fixed-angle | Supports pellet formation efficiently | Wrong tube rating or worn adapters |

Multi-purpose lab work | General-purpose + optional refrigerated | Interchangeable rotor system | Flexibility across sample types | Buying too specialized too early |

Temperature-sensitive samples | Refrigerated model (high or low speed) | Depends on tubes | Controls sample temperature during runs | Assuming “short run = no heating” always |

Tip: If you’re building a product category page or a buyer guide, this table can be a standalone “bookmark section” that improves time-on-page.

4. The Practical Differences That Affect Results

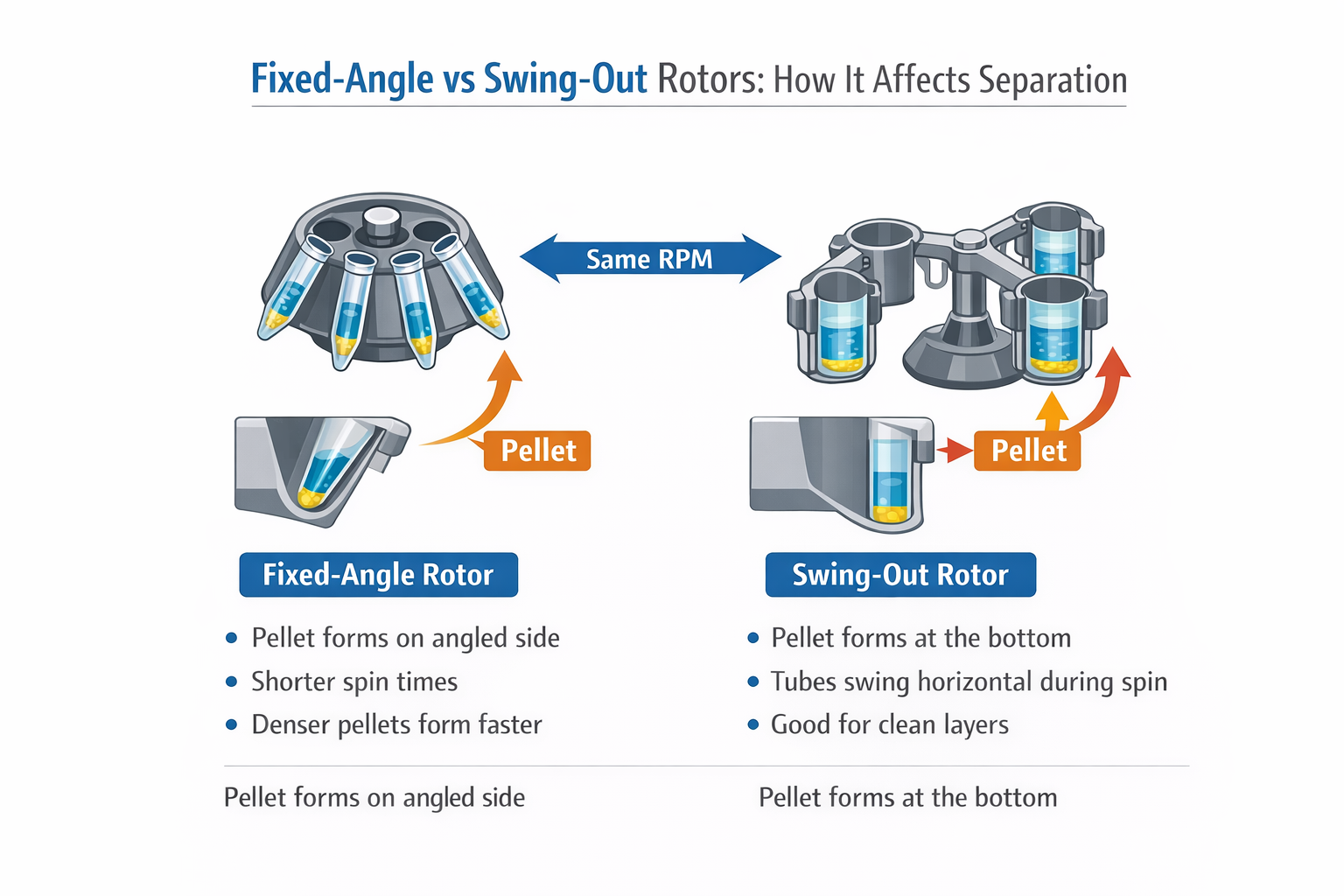

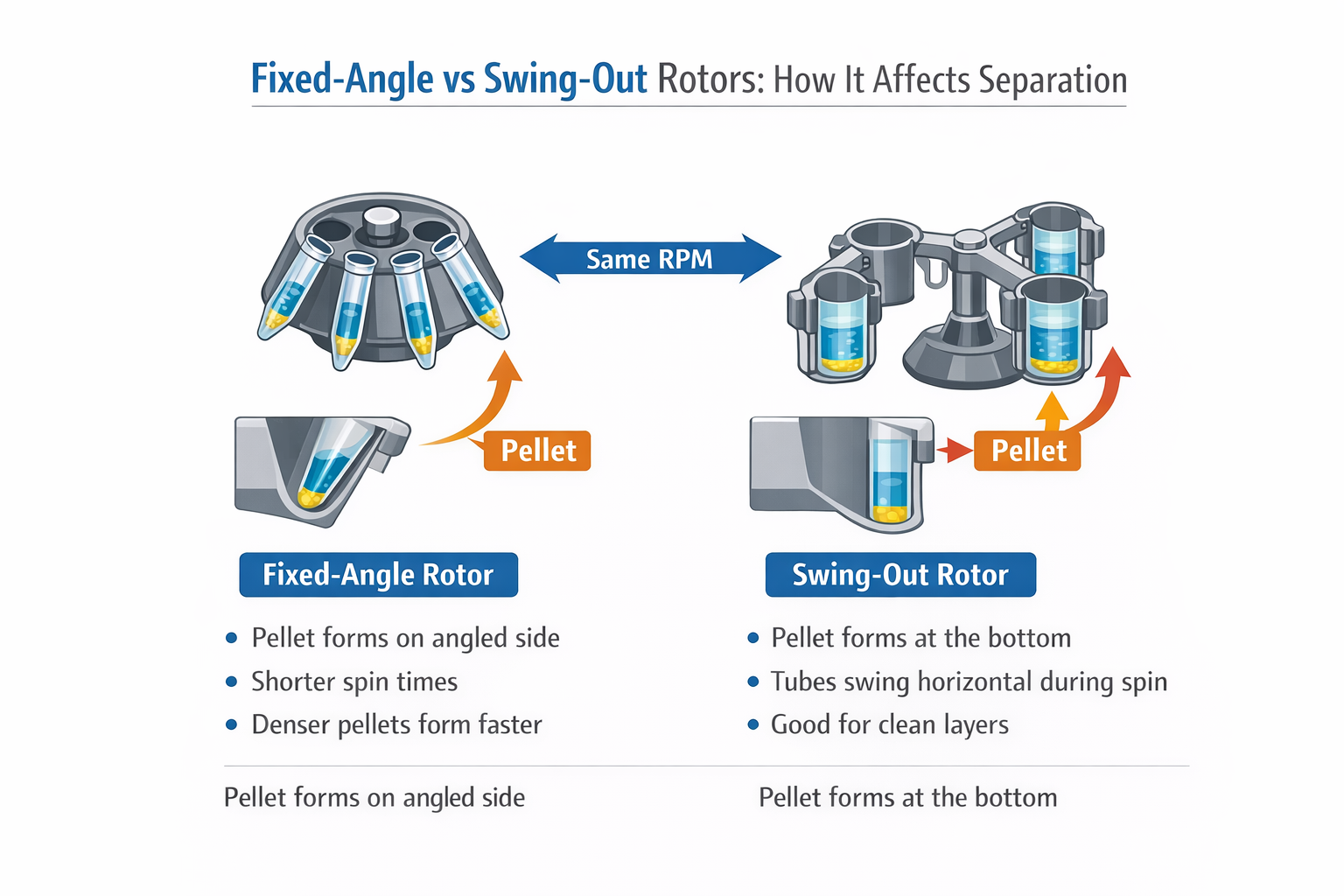

4.1 Rotor choice changes separation behavior

Even when two machines reach similar speeds, different rotors change outcomes:

Swing-out rotors often support cleaner layer separation in tubes

Fixed-angle rotors often shorten path length and can speed up pellet formation

Comparison of swing-out vs fixed-angle centrifuge rotors and pellet location.

4.2 Throughput vs gentleness

Higher speed can reduce run time, but it may also increase sensitivity to:

imbalance or tube mismatch

adapter wear

sample heating during long or repeated high-speed cycles

That’s why many labs choose a “two-machine strategy”: a routine low/medium-speed unit for daily work and a high speed centrifuge for targeted micro-volume tasks.

5. Common Problems, Causes, and Fixes

TABLE 3 — Common Centrifuge Problems & Fixes

Symptom | Likely cause | Risk level | Practical fix |

Strong vibration / walking | Tubes not balanced, mismatched adapters | High | Rebalance by mass, check adapters and tube symmetry |

Lid won’t open | Safety interlock triggered after abnormal stop | Medium | Follow reset procedure; inspect for imbalance cause |

Poor separation layers | Wrong RCF/time/rotor choice | Medium | Adjust protocol; confirm rotor supports your tubes |

Tube leakage / cracking | Tube not rated for conditions or wrong adapter | High | Use compatible, rated tubes and correct adapters |

Unexpected sample warming | Long runs, repeated high-speed cycles | Medium–High | Reduce cycle time; consider refrigerated option |

Noisy operation | Rotor wear, loose components | Medium | Inspect rotor and seating; maintain regularly |

6. Maintenance & Safety Checklist

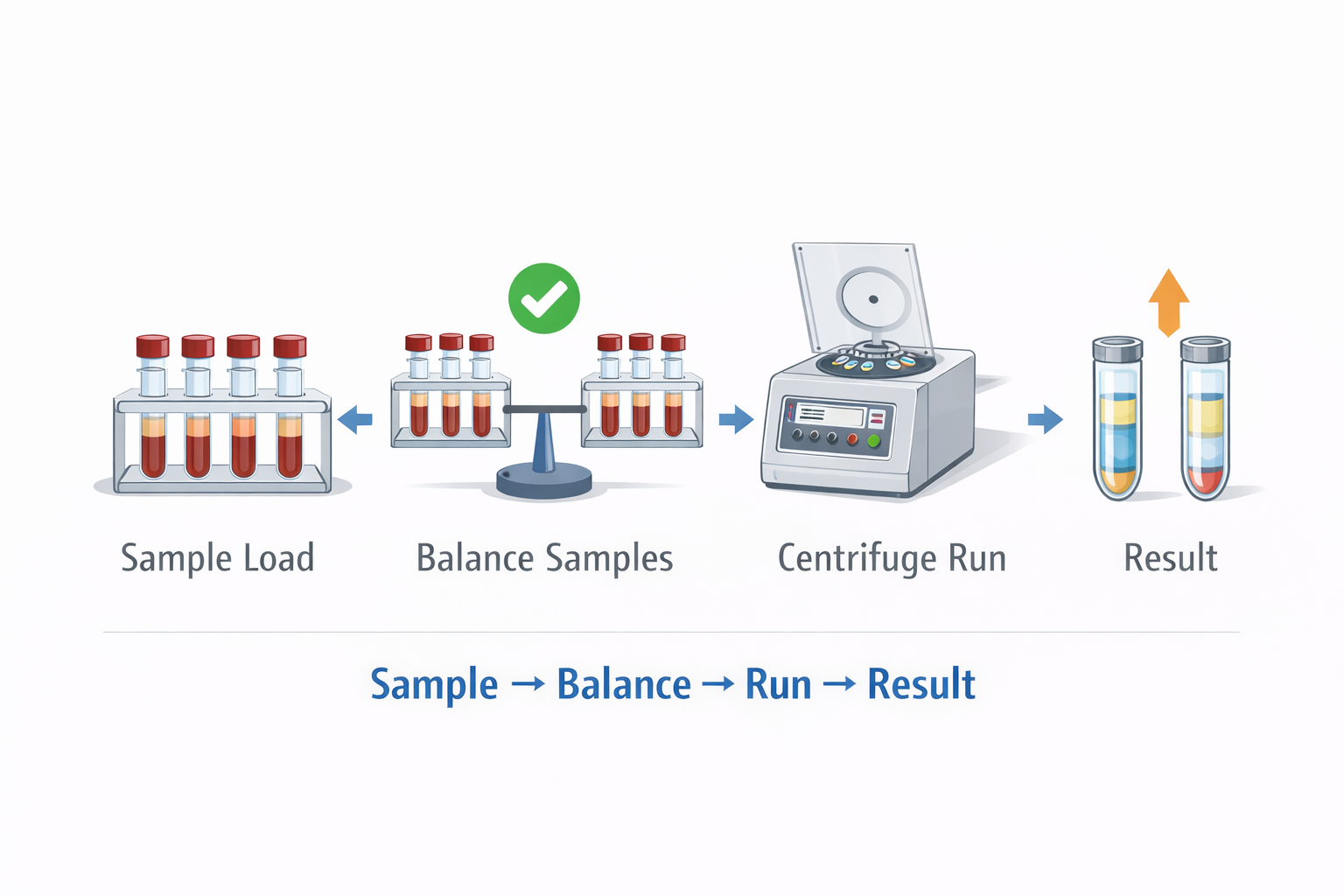

A centrifuge is a high-energy instrument. Good maintenance protects both results and operator safety. Keep it simple and procedural—readers want a checklist they can copy.

TABLE 4 — Centrifuge Maintenance Checklist

Frequency | What to do | Why it matters |

Daily | Wipe chamber, check for spills, inspect lid seal | Prevent corrosion and contamination |

Weekly | Inspect rotor surfaces and adapters | Reduces vibration and wear-related failures |

Monthly | Check rotor seating, review noise/vibration pattern | Catch early mechanical issues |

Periodic (as needed) | Calibration/verification and service checks | Supports repeatability and compliance |

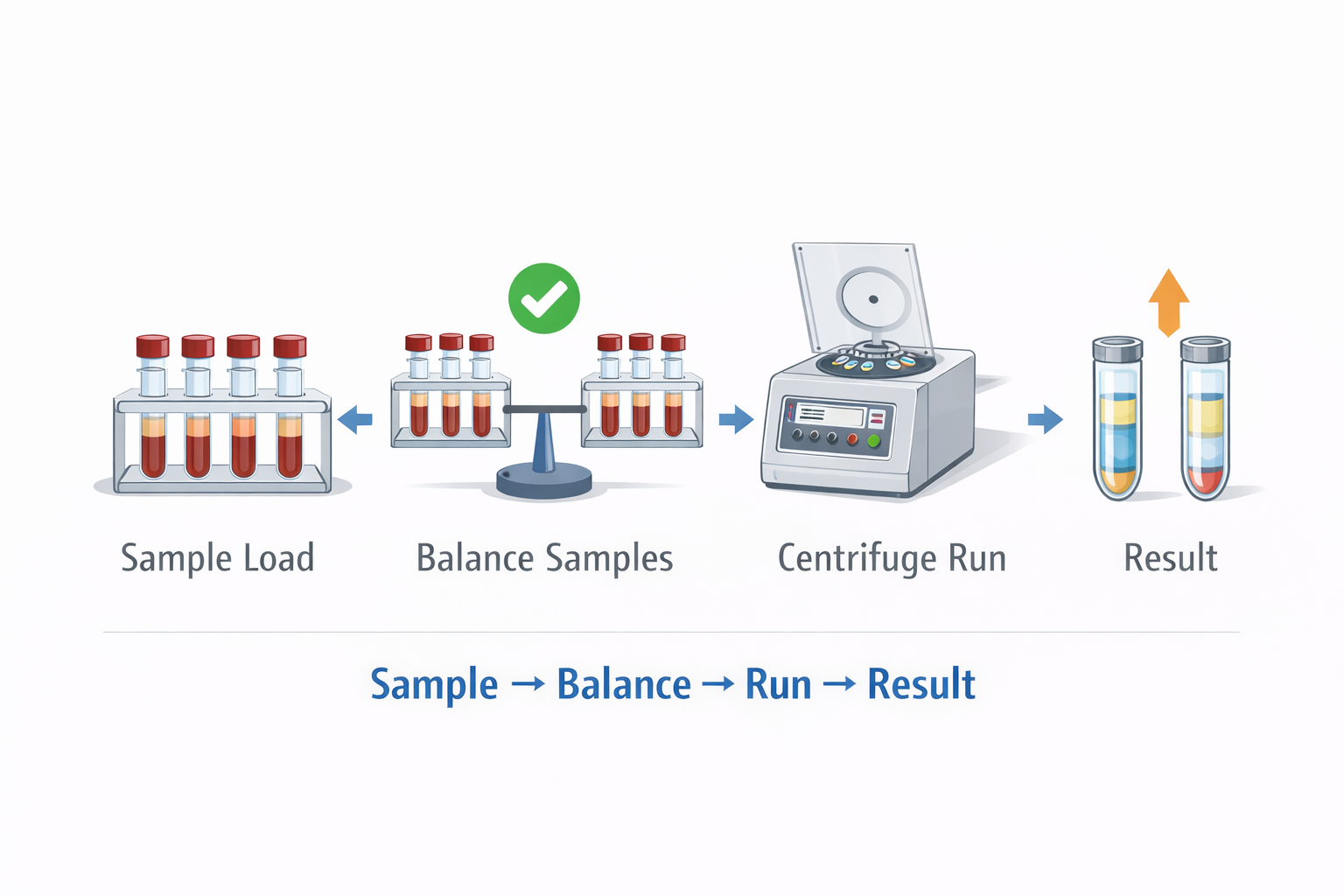

Centrifuge workflow: balancing, running, inspecting, and recording.

7. How to Choose a Supplier

Readers evaluating a high speed centrifuge often compare more than specs. A practical buyer checklist includes:

Quality system and certifications

Safety design and rotor options

Consistent manufacturing and testing

After-sales support, parts availability, and warranty terms

Optional brand notes:

Many buyers also look for suppliers with established manufacturing experience, recognized quality certifications, and clear warranty coverage—because centrifuge performance depends on long-term stability, not only maximum speed. At GlanLab, we are dedicated to providing high-quality, customizable high speed centrifuge. Contact us right now!

Conclusion

A great centrifuge decision is not “high speed vs low speed” in the abstract—it’s application matching. Use the comparison chart to understand trade-offs, use the task-based table to choose by workflow, and use the troubleshooting and maintenance checklists to protect long-term reliability.

If you’re building a lab or upgrading equipment, consider your most frequent sample types first, then confirm rotor compatibility, safety features, and support coverage. That’s how a high speed centrifuge (or a stable low/medium-speed model) becomes a long-term asset rather than a spec-sheet purchase.

FAQs

1) What is the main difference between a high speed centrifuge and a low speed centrifuge?

A high speed centrifuge is optimized for higher separation force and faster micro-volume workflows, while low/medium-speed centrifuges typically focus on routine tasks, larger tube compatibility, and everyday stability.

2) Is RPM or RCF more important when choosing a centrifuge?

RCF is often more meaningful because it reflects the actual g-force applied to your sample. RPM must be interpreted together with rotor radius.

3) When do I need a refrigerated centrifuge?

If your samples are temperature-sensitive, if you run repeated cycles, or if heat can affect stability or integrity, refrigerated models are worth considering.

4) Can one centrifuge handle both blood tubes and microtubes?

Sometimes yes, but it depends on rotor options, adapters, and workflow priorities. Many labs prefer a flexible rotor system or separate machines for peak efficiency.

5) Which rotor is better: fixed-angle or swing-out?

Swing-out rotors often support cleaner layer separation, while fixed-angle rotors can be efficient for pellet formation and short run times.

6) How do I reduce vibration at high speed?

Balance by mass, use correct tube/adapters, inspect rotor seating, and follow routine maintenance checks.

7) What safety features should I prioritize?

A strong lid lock, imbalance detection, overspeed protection, and a well-designed chamber are essential safety fundamentals.

8) What is the simplest way to pick between the two types?

Start with your sample type and target outcome. If you run micro-volume, need higher g-force, or need faster clarification, choose a high speed centrifuge. If you run routine separation and larger tubes daily, low/medium-speed models often provide the best practicality.